Industrial HVAC diagnostics and professional deep cleaning — faster, safer, measurable

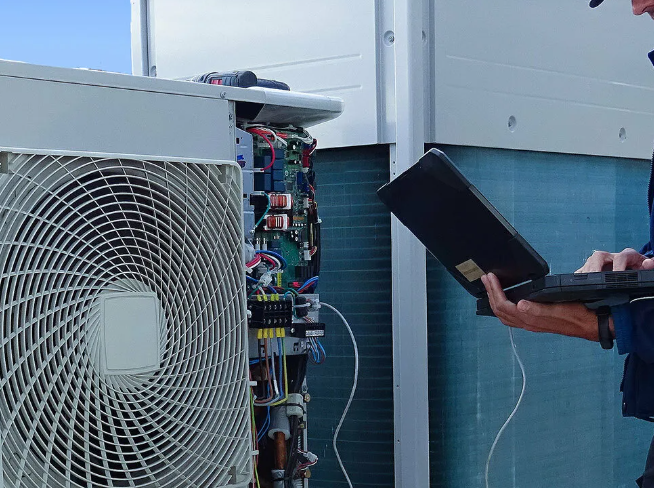

CoolCheckPro specialises in full-scope diagnostics and thorough cleaning of industrial and large commercial HVAC systems. We combine camera-based duct inspection, infrared thermography, refrigerant diagnostics, high-pressure coil extraction and eco-safe chemical cleaning to restore airflow, improve heat transfer, and recover lost capacity. Our field teams follow strict safety and containment protocols to prevent cross-contamination and ensure regulatory compliance for food, pharmaceutical and clean-room environments. Each engagement begins with a data-driven assessment: performance baselines are recorded, energy metrics are logged, and equipment histories are reviewed so remediation targets are specific and measurable.

The benefits of targeted cleaning and diagnostics extend beyond immediate air quality improvements — they translate into lower energy consumption, extended equipment life, and reduced unplanned downtime. By removing biological growth, dust-laden coatings and greasy residues from coils and internal surfaces we improve heat exchange efficiency, reduce pressure drops across filters and coils, and restore designed airflow patterns. Where necessary, we provide component-level recommendations: variable-frequency drive tuning, belt tension adjustments, and targeted replacement of compromised seals to prevent recurring issues. Our standard deliverable is a comprehensive service report with before/after images, maintenance recommendations, and energy impact estimates.

Email: coolcheckpro@live.com • Address: C. de Sta. Isabel, 5, Centro, 28012 Madrid, Spain